Services

Comprehensive Electronic Contract Assembly Services

what we offer

Our Electronic Contract Manufacturing Services

Comprehensive Electronic Contract Assembly Services

Advanced Manufacturing Services strives to provide our customers with a complete electronic assembly experience. Our dedicated experts and state-of-the-art facilities use the latest techniques to produce high-quality results at highly competitive prices.

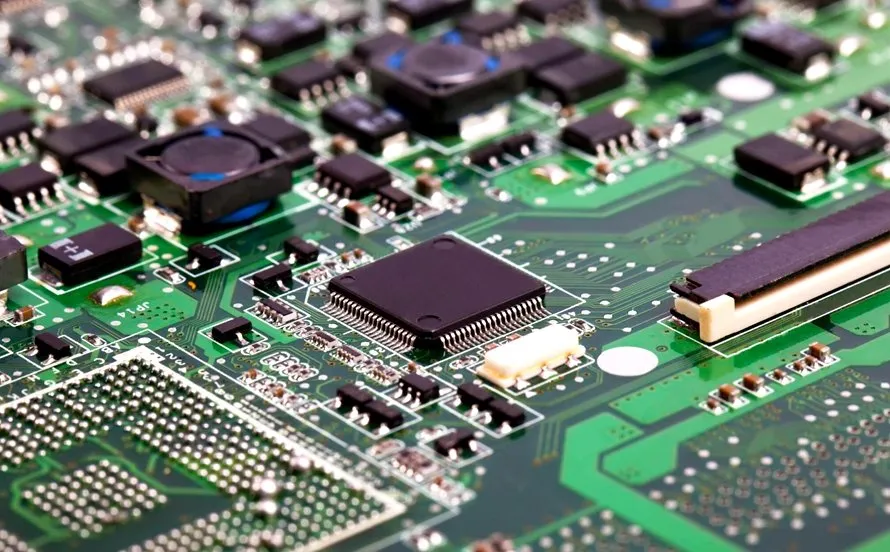

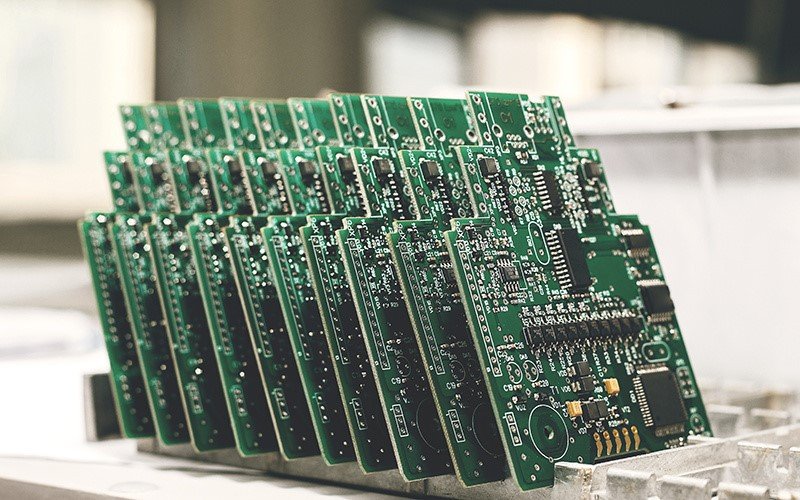

Printed Circuit Board (PCB) Assembly

Specializing in low volume high-mix production of custom PCB assemblies, designed by experts and built by passionate professionals.

Lead Free (RoHS) and Non-RoHS Assembly

With both RoHS and Non-RoHS assembly capabilities, we have the flexibility to meet our customers’ exact requirements.

Prototype Fabrication

As a full-service electronic assembly provider, we proudly offer comprehensive prototype fabrication services that help streamline production processes.

Turnkey and Consigned Material

Advanced Manufacturing Services maintains a wide range of materials in stock for rapid delivery of just-in-time assemblies. We also nurture extensive relationships with trusted suppliers, ensuring prompt delivery of cost-effective and high-quality consigned components.

Surface Mount Assembly (SMT)

Every certified AMS assembly technician undergoes rigorous ongoing training to ensure continued compliance with strict IPC-A-610 class II and III soldering standards for reliable connections.

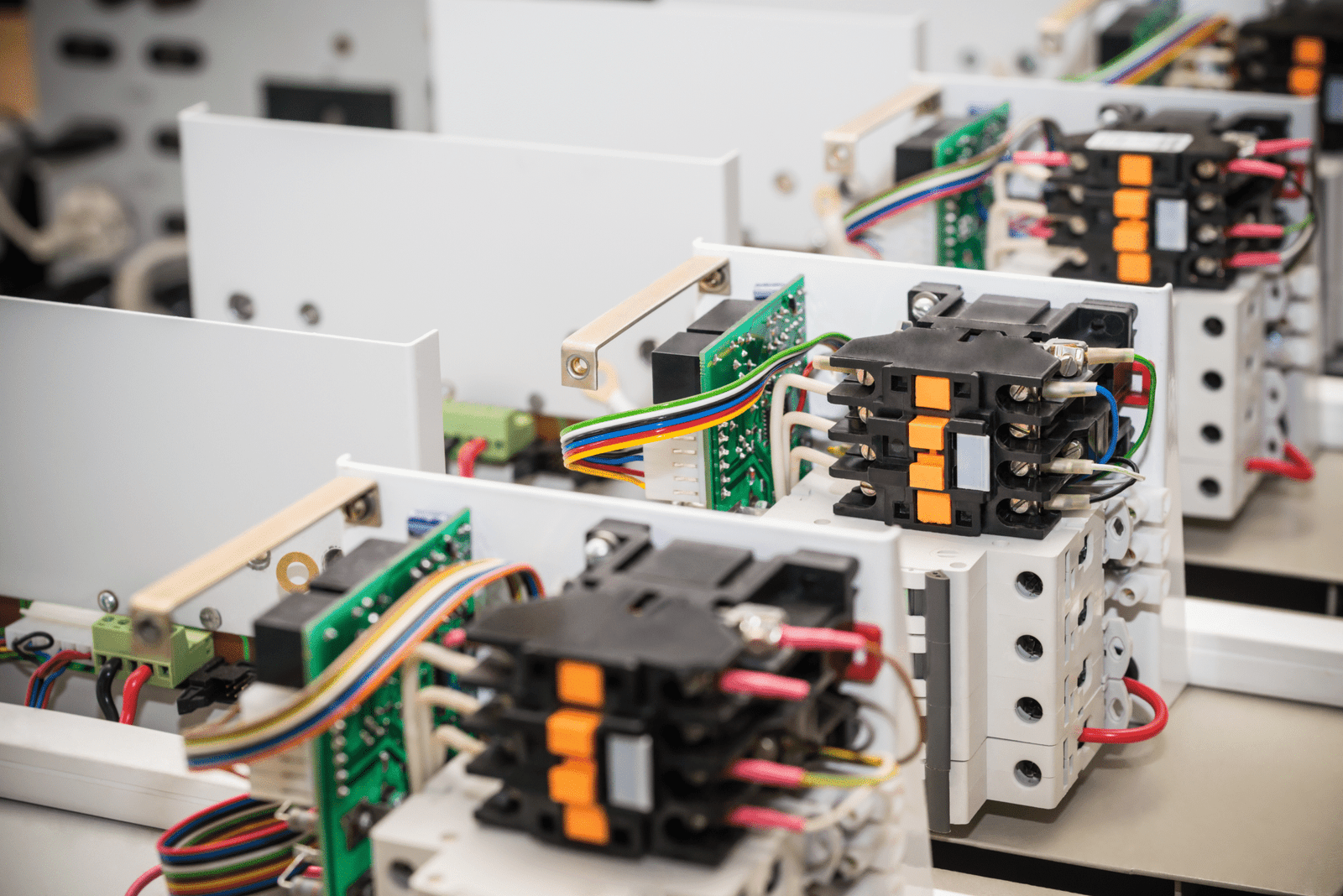

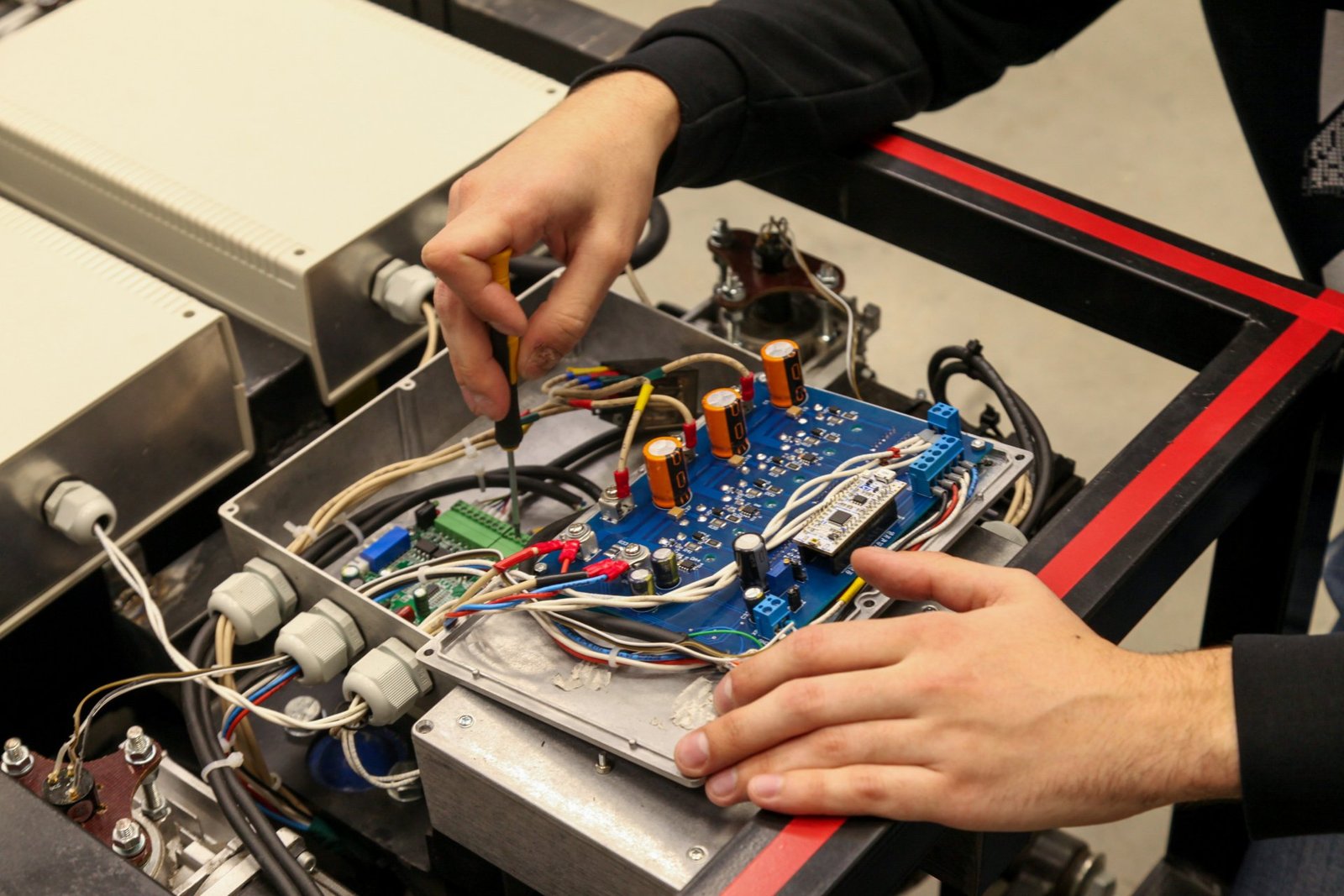

Electro-Mechanical Assembly

Our innovative assembly solutions for complex electro-mechanical projects help streamline the assembly process while ensuring consistently high-quality results.

Functional Testing

Our functional testing process is an extension of our commitment to customer satisfaction and ISO 9001:2015-certified quality management system, ensuring every assembly works exactly as intended.

Your One Source for All Your Manufacturing Needs

From prototype to full production, we do it all. Contact us today to learn more about our comprehensive electronic contract manufacturing services.

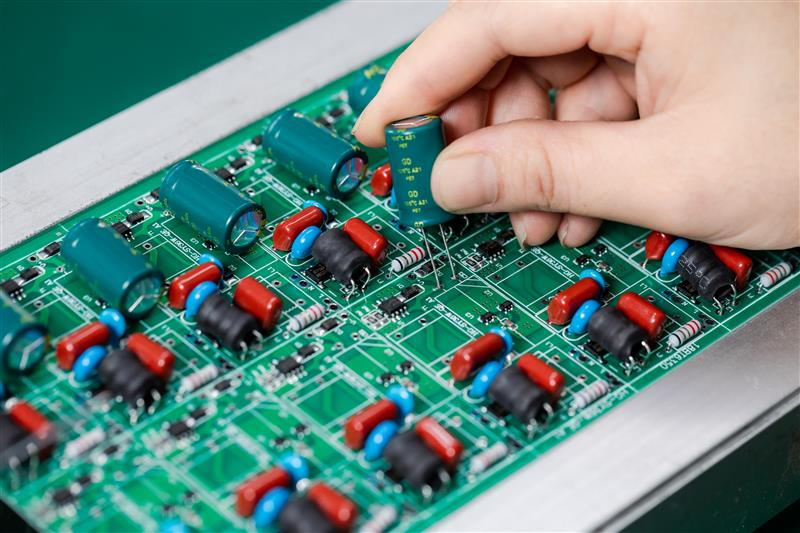

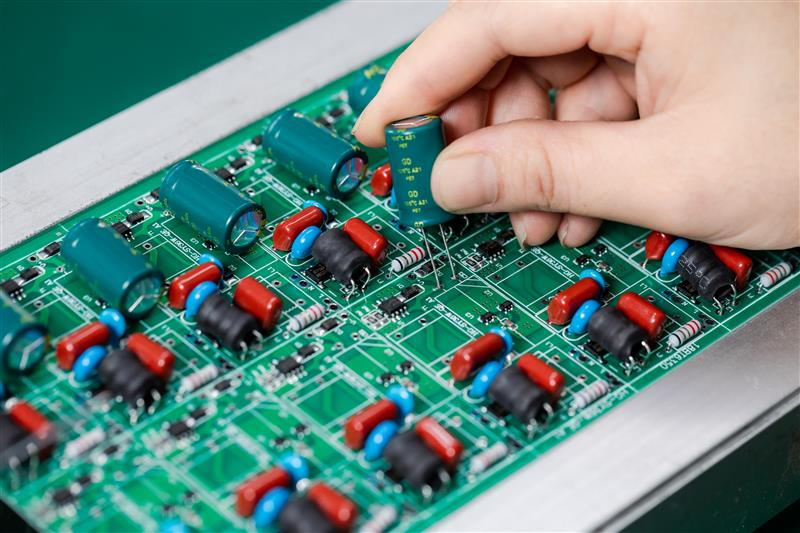

Through Hole Assembly (PTH)

Our highly experienced PTH assembly technicians use time-tested methods combined with advanced technologies to help improve connection durability for components used in harsh environments.

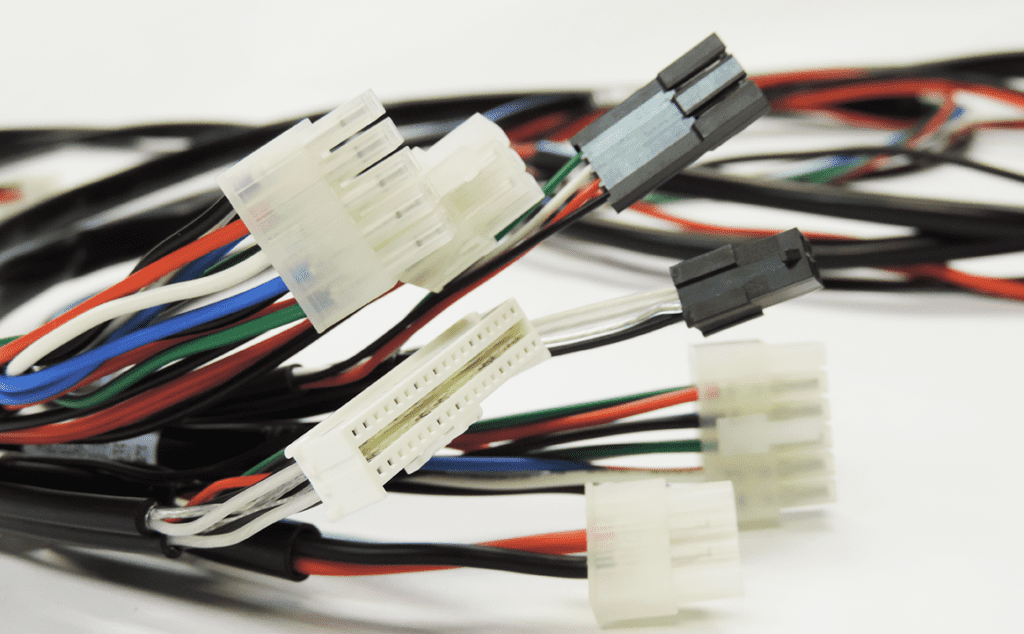

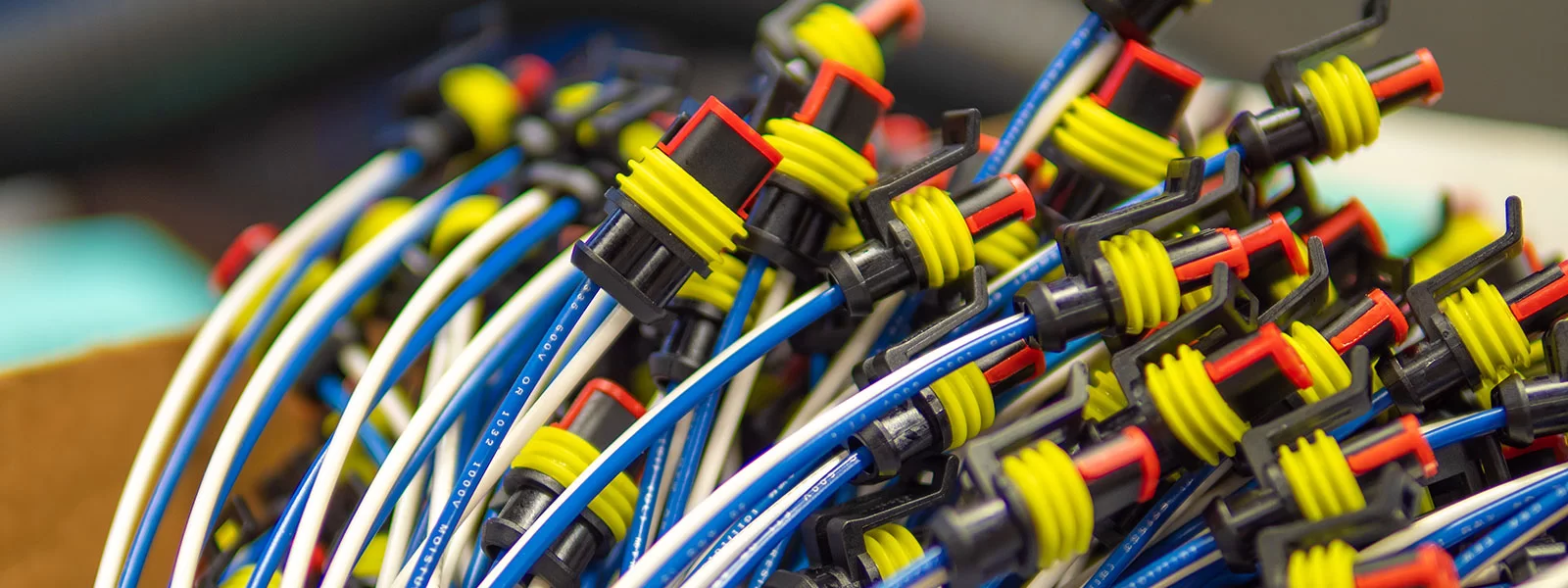

Cable and Wire Harness Assembly

We use our extensive experience to create custom harness assemblies that keep wires and cables in check while ensuring reliable connections to the PCB and long-term dependability.

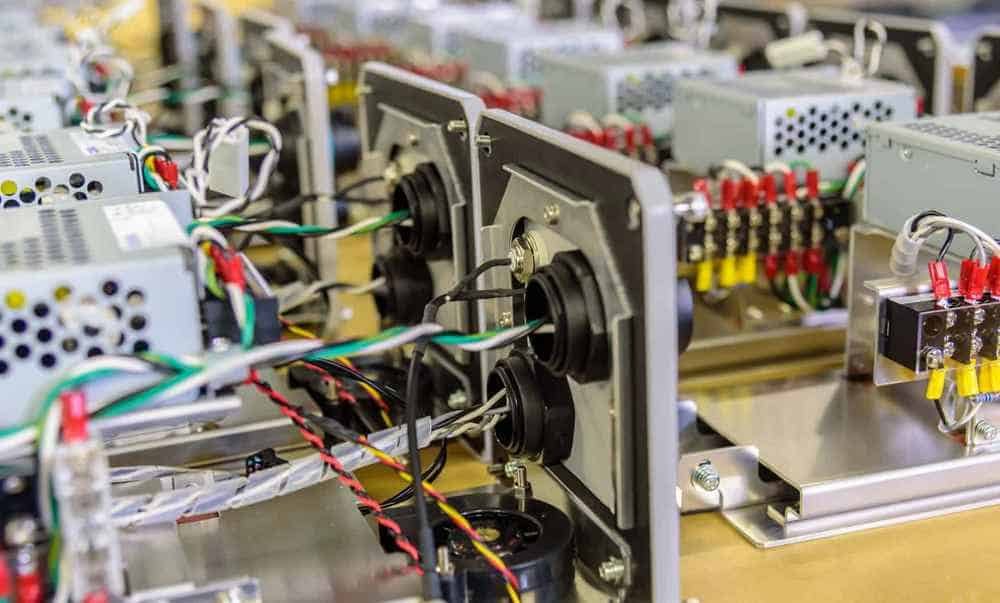

Box Build

We are a full-service manufacturer that offers expert box build services to reduce costs by keeping the assembly process in-house. Workmanship to IPC-610 Class II & Class III

When you need a reliable partner to manufacture your products, we are here to help

Magna ac placerat vestibulum lectus mauris ultrices eros in. Ornare lectus sit amet est. Quam elementum pulvinar etiam non quam. Sociis natoque penatibus et magnis dis parturient montes nascetur. Mi quis hendrerit dolor magna eget est. Mauris ultrices eros in cursus turpis massa tincidunt dui ut. Natoque penatibus et magnis dis parturient montes. A scelerisque purus semper eget. Auctor eu augue ut lectus arcu bibendum.

Vel facilisis volutpat est velit egestas. Vitae proin sagittis nisl rhoncus mattis. Interdum velit laoreet id donec ultrices tincidunt arcu non sodales. Nisl purus in mollis nunc sed. Ornare arcu odio ut sem nulla pharetra. Porttitor eget dolor morbi non arcu risus quis. Non blandit massa enim nec dui nunc. Lectus magna fringilla urna porttitor rhoncus dolor. Nunc sed augue lacus viverra vitae. Elit pellentesque habitant morbi tristique senectus et netus.

Eget duis at tellus at urna condimentum. Varius duis at consectetur lorem donec massa sapien faucibus et. Vel quam elementum pulvinar etiam non quam. Facilisi nullam vehicula ipsum a. Imperdiet massa tincidunt nunc pulvinar sapien et ligula ullamcorper. Ornare suspendisse sed nisi lacus sed viverra tellus in. Tortor at auctor urna nunc. Eros donec ac odio tempor orci dapibus ultrices. Pretium lectus quam id leo in vitae.

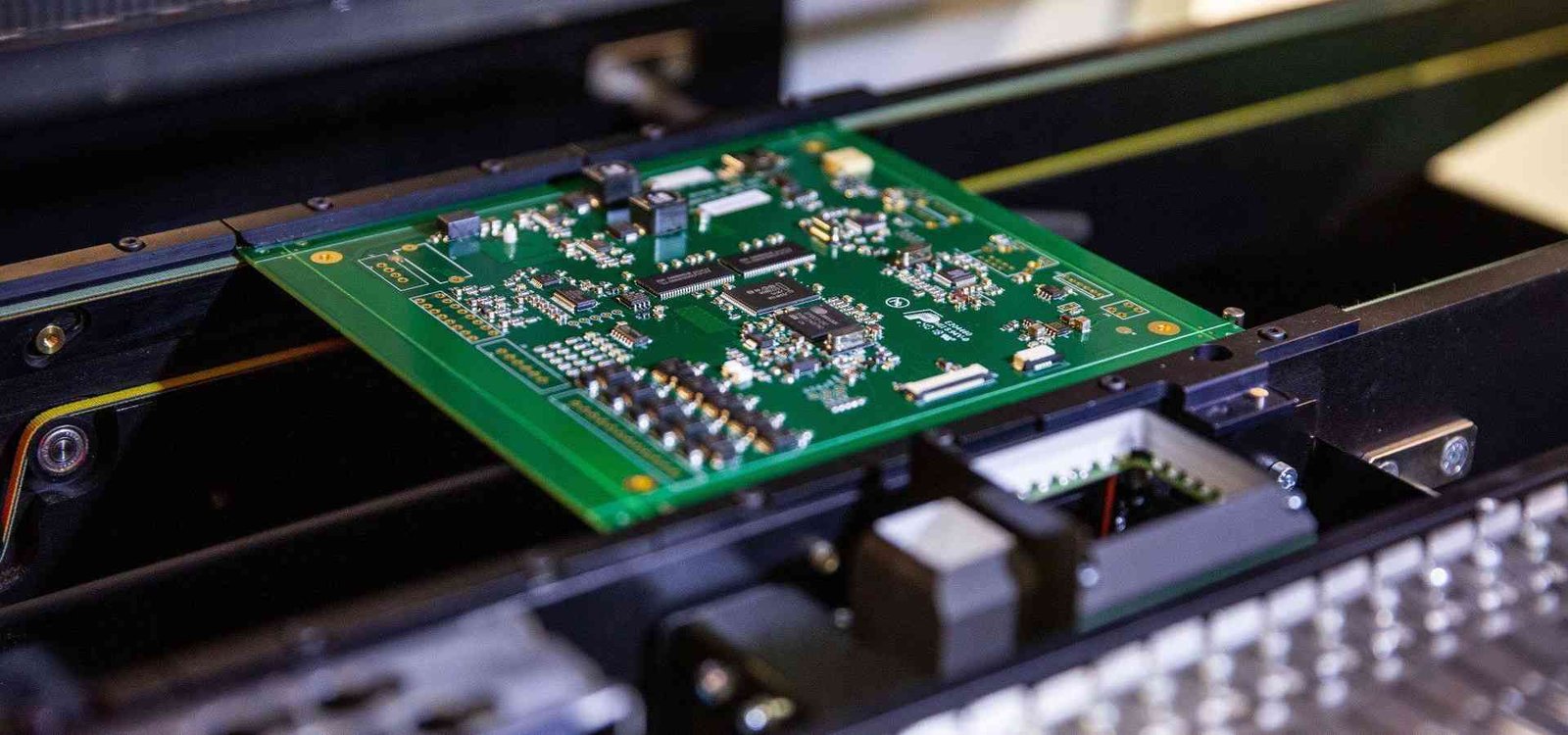

Accelerating Your Success with Rapid PCB Prototype Fabrication

Advanced Manufacturing Service, Inc. proudly maintains a comprehensive and cutting-edge manufacturing facility in Ronkonkoma, NY to provide our customers with rapid delivery of their PCB prototypes, from quote to delivery, in as little as a week. Manufactured and assembled in the United States by highly skilled experts under the strict standards of our ISO 9001:2015-certified quality management system ensures on-time delivery of functional and high-quality PCB and electronic assembly prototypes.

Box Build

Custom Solutions for Electronic Box Build Requirements

Advanced Manufacturing Service: Expert Box Build Services

AMS has built a reputation for excellence in precision assembly for complex kitted or sourced box builds for electro-mechanical assemblies used across demanding applications in some of the world’s most critical industries, including but not limited to:

- Aerospace & Defense

- LED Technologies

- Medical Equipment

- Industrial Controls

All manufacturing is conducted under strict ESD-safe protocols and in accordance with the stringent quality standards of our ISO 9001:2015 certification. Our technicians are certified to J-STD-001 and ICP-A-610 Class II & III. We have extensive experience following complex diagrams to ensure all box builds meet exact specifications while exceeding expectations for timely delivery.

Advanced Manufacturing Service: Expert Box Build Services

AMS has built a reputation for excellence in precision assembly for complex kitted or sourced box builds for electro-mechanical assemblies used across demanding applications in some of the world’s most critical industries, including but not limited to:

- Aerospace & Defense

- LED Technologies

- Medical Equipment

- Industrial Controls

All manufacturing is conducted under strict ESD-safe protocols and in accordance with the stringent quality standards of our ISO 9001:2015 certification. Our technicians are certified to J-STD-001 and ICP-A-610 Class II & III. We have extensive experience following complex diagrams to ensure all box builds meet exact specifications while exceeding expectations for timely delivery.

Taking Control of the Supply Chain

AMS is more than just a trusted supplier of reliable custom box builds, we are your one source for all your electronic manufacturing needs. AMS has developed trusted relationships with quality component suppliers to help source the highest quality box build components for the best value, allowing us to pass the savings on to our customers.

To ensure timely delivery, we maintain a vast inventory of electronic components and utilize a powerful MRP system for supply chain management. From our extensive partnerships with the industry’s leading component suppliers to our state-of-the-art printed circuit board assembly capabilities, we have what it takes to get the job done fast.

Complete Turnkey Box Build Assembly

From component procurement to custom packaging, we proudly offer complete turnkey assembly services for box builds used across a wide range of applications. We continually strive to streamline our customers’ production process, enhancing efficiency, and reducing costs through innovative solutions to their box build requirements. Since 2007, we have developed extensive capabilities to support a wide range of electronic components, including:

- Printed Circuit Board Assemblies

- Mechanical Assemblies

- Cable Harness Assemblies

Our comprehensive manufacturing facility includes cutting-edge technology that rapidly produces high-quality custom printed circuit boards and wire harnesses exactly to specifications. This in-house manufacturing allows us to reduce production time and overall production costs.

Contact Advanced Manufacturing Service to learn more about our custom box build service and request your quote today!

Electro-Mechanical Assembly

Comprehensive Assembly Capabilities for Complex Requirements

Your Partner for Comprehensive Electromechanical Assembly

Advanced Manufacturing Service proudly maintains comprehensive manufacturing capabilities and a team of highly skilled, IPC-A-610 Class II and III certified professionals with extensive experience building complex electromechanical assemblies. From printed circuit boards to cable harness assemblies, to complete box builds, we can handle it all.

Custom Printed Circuit Board Assemblies

We specialize in high mix low volume manufacturing of custom printed circuit board assemblies. This allows us to rapidly produce several PCBs to incorporate into a single electromechanical assembly.

Complex Cable Harness Assemblies

We have developed proven techniques to create custom cable and wire harness assemblies that protect these vital components from becoming dislodged during their intended operations.

Box Builds

We couldn’t claim to be a single source manufacturer if we didn't have quality box build capabilities, ensuring on-time delivery of low to medium volume requirements.

Expert Mechanical Assembly

After sourcing or manufacturing, all required components, our team expertly combines them exactly to specifications creating dependable mechanical assemblies.

From Prototyping to Production

Since 2007 AMS has been dedicated to providing our customers with the highest level of quality and customer service. By utilizing the industry’s leading technology combined with the detail-oriented focus of our highly skilled staff, we’re able to deliver quick-turn prototypes that seamlessly transition to production volume.

From Prototyping to Production

Since 2007 AMS has been dedicated to providing our customers with the highest level of quality and customer service. By utilizing the industry’s leading technology combined with the detail-oriented focus of our highly skilled staff, we’re able to deliver quick-turn prototypes that seamlessly transition to production volume.

Meeting Global Quality Standards

In a testament to our dedication to absolute quality, we maintain a strict ISO 9001:2015-certified quality management system that provides component-level traceability when required. Every electromechanical assembly is manufactured in a robust ESD environment to ensure each sensitive component is protected.

We’re Ready for Our Next Challenge

Electromechanical assemblies are some of the most complex projects due to the mix of electronic components and mechanical features. We love the challenge these projects bring as they allow us to flex our manufacturing and assembly capabilities.

Contact Advanced Manufacturing Service to learn more or request a quick-turn quote today!

Functional Testing

Reliably Accurate Results

Robust Inspection Processes

Advanced Manufacturing Service proudly maintains a strict ISO 9001:2015-certified quality management system that oversees every aspect of production from start to finish, including end-of-the-line functional testing and burn-in. To ensure absolute customer satisfaction every unit undergoes thorough inspections before we ship completed products out to customers.

Robust Inspection Processes

Advanced Manufacturing Service proudly maintains a strict ISO 9001:2015-certified quality management system that oversees every aspect of production from start to finish, including end-of-the-line functional testing and burn-in. To ensure absolute customer satisfaction every unit undergoes thorough inspections before we ship completed products out to customers.

Functional Testing

Ensuring every printed circuit board assembly performs exactly as required is an essential part of the manufacturing process, one that typically happens at the end of the line. Completed assemblies are tested in a specially designed device that provides detailed information about the performance of the PCB assembly. Here at AMS, we utilize the industry’s most trusted functional testing equipment and maintain extensive documentation capabilities and component-level traceability.

Burn-In

Our customers demand reliable components and assemblies that not only perform exactly as required but also will produce reliable results over prolonged periods. To detect early failure and potential defects, we maintain extensive burn-in capabilities that allow us to stress electronic devices under high-temperature conditions. This prevents costly delays and reworking.

Burn-In

Our customers demand reliable components and assemblies that not only perform exactly as required but also will produce reliable results over prolonged periods. To detect early failure and potential defects, we maintain extensive burn-in capabilities that allow us to stress electronic devices under high-temperature conditions. This prevents costly delays and reworking.

Advanced Manufacturing Service is Committed to Quality

We are committed to consistently providing products that meet or exceed customer and industry requirements. We are dedicated to the continual improvement of our processes and services and maintain robust quality management and EDS-safe manufacturing facility. AMS works closely with our customers and suppliers to foster long-term relationships.

Contact Advanced Manufacturing Service to learn more about our PCB testing capabilities and request your quote today.

Lead Free (RoHS) & Non RoHS Assembly

Flexible Manufacturing Capabilities for All Printed Circuit Board Requirements

Your One Source for Quality Printed Circuit Board Assemblies

Since 2007, Advanced Manufacturing Service has been committed to providing our clients with comprehensive PCB assembly services utilizing the industry’s latest technology and techniques. Our extensive capabilities include both lead free assembly and non RoHS assembly, providing flexible manufacturing options to meet our clients’ unique requirements.

Your One Source for Quality Printed Circuit Board Assemblies

Since 2007, Advanced Manufacturing Service has been committed to providing our clients with comprehensive PCB assembly services utilizing the industry’s latest technology and techniques. Our extensive capabilities include both lead free assembly and non RoHS assembly, providing flexible manufacturing options to meet our clients’ unique requirements.

Lead Free Assembly Capabilities

Since 2006, more and more electronics are relying on lead free (RoHS) assemblies as the industry embraces cleaner manufacturing policies. The Restriction of Hazardous Substances (RoHS) is a European Union directive that has grown in global popularity and is becoming adopted by many states throughout the United States.

Many of our clients require RoHS compliant PCB assemblies to meet the regulatory requirements of their states, industry, or end consumer demands. Other times, our customers require lead free (RoHS) assemblies to better align with their company’s environmental policies. Regardless of their reasons for seeking lead free assembly, AMS has the experience and equipment to rapidly produce high quality assemblies that meet RoHS requirements.

Non RoHS Assembly Capabilities

While the electronics industry may be steering away from Non RoHS assemblies due to their potential negative impacts on the environment and assembly technician health, AMS maintains a dedicated Non RoHS assembly line for our customers who require or prefer the traditional tin-lead solder. We take special measures to ensure the health and safety of our employees, reducing their exposure to potentially harmful substances while meeting the needs of our customers.

Non RoHS Assembly Capabilities

While the electronics industry may be steering away from Non RoHS assemblies due to their potential negative impacts on the environment and assembly technician health, AMS maintains a dedicated Non RoHS assembly line for our customers who require or prefer the traditional tin-lead solder. We take special measures to ensure the health and safety of our employees, reducing their exposure to potentially harmful substances while meeting the needs of our customers.

World Class Customer Service for Global Success

Reliable, high-quality printed circuit board assemblies can make or break an OEMs success and when they expand into the global market, they need to ensure their PCBs meet international regulations as well as strict quality standards. At AMS, we work closely with our customers to develop cost effective solutions to their lead free assembly requirements, including full turnkey or consigned material.

Contact Advanced Manufacturing Service to learn more about our lead free and non RoHS assembly capabilities or request a quote today.

Surface Mount Assembly (SMT)

Prototype to Production Volumes

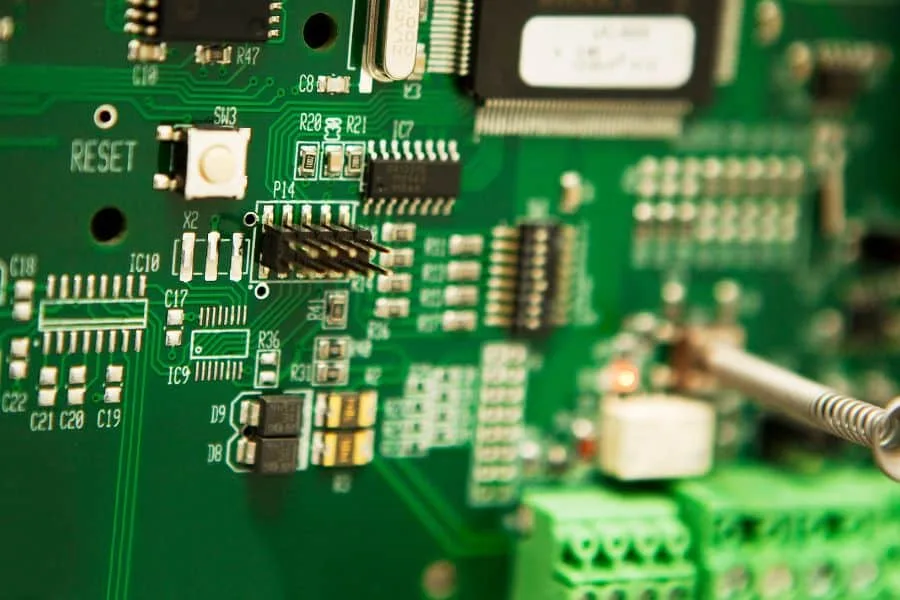

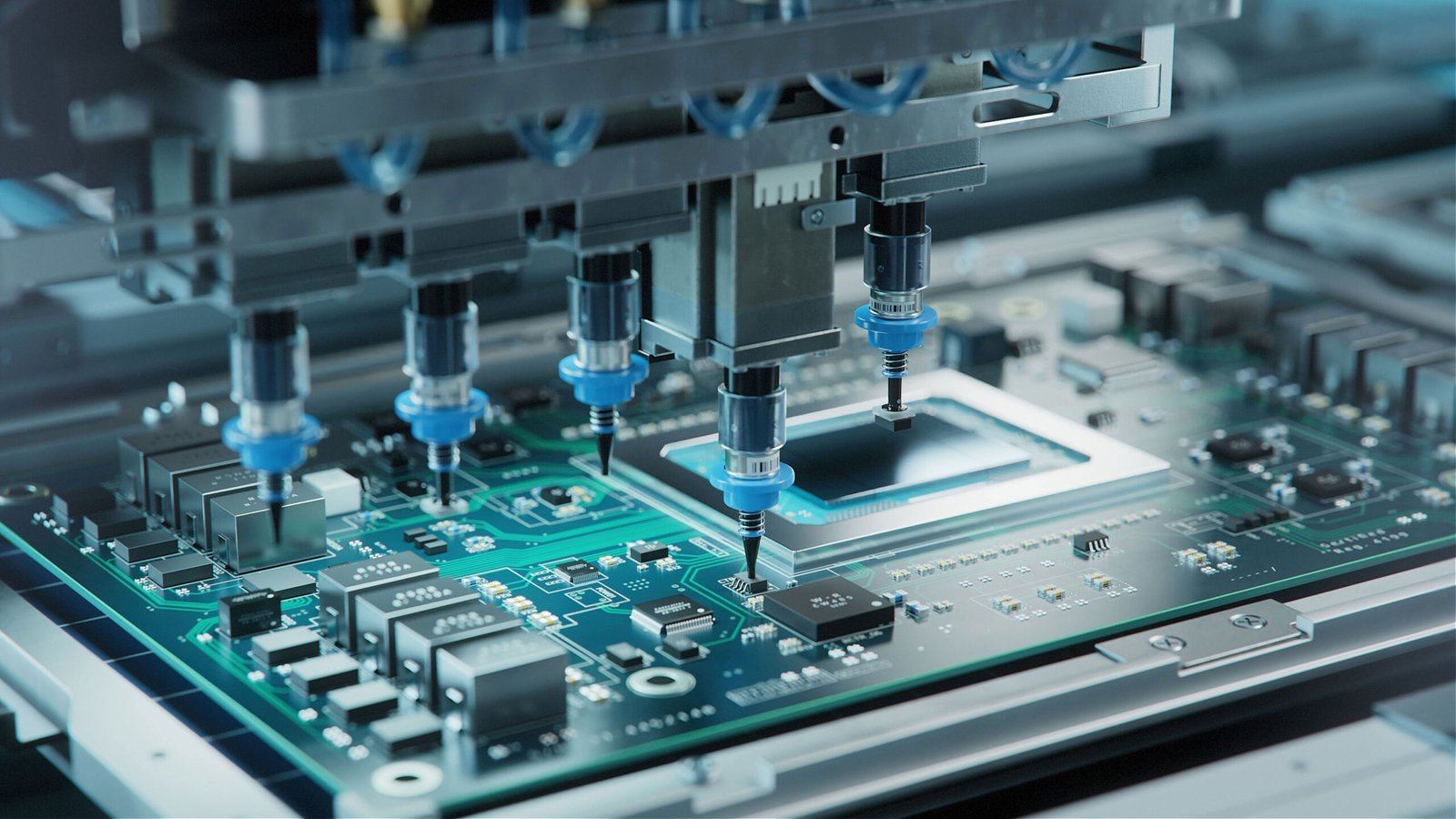

Automated SMT Circuit Board Assembly

Surface Mount Assembly (SMT) is assembling and soldering electronic components directly onto the surface of the printed circuit board (PCB) using solder paste and a reflow process that establishes the electronic connection. Advanced Manufacturing Service utilizes the industry’s most advanced technology to rapidly produce custom SMT circuit board assemblies. Our cutting-edge assembly capabilities include state-of-the-art screen printers and pick-and-place equipment compatible with a wide range of electronic components from 0402 through BGA and Fine Pitch.

At AMS, we use the latest automated processes to further reduce production times, allowing us to specialize in low to medium-volume high-mix electronic manufacturing. Streamlining Electronic Devices for Improved Efficiency

SMT circuit board assemblies are becoming increasingly popular as electronic devices become smaller and more streamlined. SMT assemblies produce lower profile results and are able to achieve smaller form factors over the traditional thru-hole assembly . Due to the more uniform connections produced through reflow methods, SMT technologies provide a more secure and dependable solution from hand-soldered components. Manufacturing SMT assemblies requires advanced manufacturing capabilities that seamlessly integrate into additional automated processes, allowing for higher production efficiency and reduced production costs.

Automated SMT Circuit Board Assembly

Surface Mount Assembly (SMT) is assembling and soldering electronic components directly onto the surface of the printed circuit board (PCB) using solder paste and a reflow process that establishes the electronic connection. Advanced Manufacturing Service utilizes the industry’s most advanced technology to rapidly produce custom SMT circuit board assemblies. Our cutting-edge assembly capabilities include state-of-the-art screen printers and pick-and-place equipment compatible with a wide range of electronic components from 0402 through BGA and Fine Pitch.

At AMS, we use the latest automated processes to further reduce production times, allowing us to specialize in low to medium-volume high-mix electronic manufacturing. Streamlining Electronic Devices for Improved Efficiency

SMT circuit board assemblies are becoming increasingly popular as electronic devices become smaller and more streamlined. SMT assemblies produce lower profile results and are able to achieve smaller form factors over the traditional thru-hole assembly . Due to the more uniform connections produced through reflow methods, SMT technologies provide a more secure and dependable solution from hand-soldered components. Manufacturing SMT assemblies requires advanced manufacturing capabilities that seamlessly integrate into additional automated processes, allowing for higher production efficiency and reduced production costs.

When Quality, Dependability, and Price Matter

Advanced Manufacturing Service is dedicated to ensuring our customers’ complete satisfaction through rapid delivery of quality and dependable SMT circuit board assembly service utilizing the industry’s latest pick and place technology to ensure affordable precision results across all production volume requirements. AMS maintains a robust quality management system certified to ISO 9001:2015 standards, and our in-house quality control process includes detailed inspections of every single unit. Our highly trained technicians are certified to J-STD-001 and IPC-A-610 Class II & III standards to ensure absolute quality and dependability.

Your One Source for Quality Electronic Manufacturing

We strive to be the leading provider of turnkey electronic manufacturing and boast comprehensive capabilities from prototyping to production. Our extensive inventory of high-quality trusted electronic components and trusted partnerships ensures on-time delivery of custom SMT circuit board assemblies.

Contact AMS to learn more and request your quote today to get started.

Thru-Hole Assembly (PTH)

Experienced PTH Assembly Services

Certified Experts in Through-Hole Assembly

Advanced Manufacturing Service is dedicated to providing our customers with the highest level of customer service with high-quality dependable through-hole assembly. We maintain one of the industry’s most robust quality management systems certified to meet the strictest ISO 9001:2015 standards. Our highly skilled assembly technicians are certified to J-STD-001 and IPC-A-610 Class II and III standards, ensuring dependable reliability in the harshest applications.

AMS is proud to work with some of the most vital industries and maintains ITAR registration with extensive documentation and component-level traceability as required for our aerospace and defense partners.

Certified Experts in Through-Hole Assembly

Advanced Manufacturing Service is dedicated to providing our customers with the highest level of customer service with high-quality dependable through-hole assembly. We maintain one of the industry’s most robust quality management systems certified to meet the strictest ISO 9001:2015 standards. Our highly skilled assembly technicians are certified to J-STD-001 and IPC-A-610 Class II and III standards, ensuring dependable reliability in the harshest applications.

AMS is proud to work with some of the most vital industries and maintains ITAR registration with extensive documentation and component-level traceability as required for our aerospace and defense partners.

State-of-the-Art Rapid PTH Assembly

All manufacturing is done in our state-of-the-art manufacturing facility with extensive ESD-safety features, down to the specialized floor coating. We have extensive experience producing precision results for complex through-hole assembly requirements and our comprehensive capabilities ensure rapid delivery of custom through-hole assemblies. To better serve our customers, we maintain a vast inventory of the industry’s most trusted components and nurture valuable partnerships to source additional components as required.

Turnkey Electronic Assembly

At AMS, we are dedicated to providing our customers with a single source for their electronic manufacturing. From custom PTH assembly to box builds and functional testing, Advanced Manufacturing Service has the experience and equipment to rapidly meet low to medium-volume high-mix printed circuit board production with comprehensive services, including:

- Mechanical Assembly

- Cable Harness Assembly

- Box Builds

- Prototype Fabrication

- Functional Testing

Turnkey Electronic Assembly

At AMS, we are dedicated to providing our customers with a single source for their electronic manufacturing. From custom PTH assembly to box builds and functional testing, Advanced Manufacturing Service has the experience and equipment to rapidly meet low to medium-volume high-mix printed circuit board production with comprehensive services, including:

- Mechanical Assembly

- Cable Harness Assembly

- Box Builds

- Prototype Fabrication

- Functional Testing

Committed to Customer Satisfaction, Dedicated to Dependable Quality

Since 2007, Advanced Manufacturing Service has proudly developed long-term partnerships with our customers by providing superior customer service, prompt delivery, and exceptional quality. When it comes to dependable through-hole assembly, our customers know they can trust us to produce precision results across all production volume requirements.

Don’t wait, contact the experts at AMS today to get your PTH assembly quote.

Turnkey and Consigned Material

Flexible Solutions for Quality Component Procurement

Extensive Inventory of the Industry’s Leading Electronic Components

Advanced Manufacturing Service is dedicated to ensuring rapid delivery of high-quality custom printed circuit board (PCB) assemblies by maintaining an extensive inventory of electronic components compatible with:

- Surface Mount Assembly

- Through-Hole Assembly

- Cable and Wire Harness Assembly

- Lead Free (RoHS) and Non RoHS Assembly

Our extensive inventory includes carefully selected electronic components, sourced from highly reputable suppliers with a history of quality and the best possible prices. This allows us to pass the savings on to our customers without compromising speed or quality.

Extensive Inventory of the Industry’s Leading Electronic Components

Advanced Manufacturing Service is dedicated to ensuring rapid delivery of high-quality custom printed circuit board (PCB) assemblies by maintaining an extensive inventory of electronic components compatible with:

- Surface Mount Assembly

- Through-Hole Assembly

- Cable and Wire Harness Assembly

- Lead Free (RoHS) and Non RoHS Assembly

Our extensive inventory includes carefully selected electronic components, sourced from highly reputable suppliers with a history of quality and the best possible prices. This allows us to pass the savings on to our customers without compromising speed or quality.

Network of Trusted Partnerships

When our customers require specialized electronic components we tap into our extended network of the industry’s most trusted suppliers to source the best quality at the best prices, delivered as quickly as possible. This network of trusted partnerships ensures rapid delivery of high-quality electronic assemblies exactly to our customer’s unique specifications.

Comprehensive Electronic Manufacturing Capabilities

Regardless of where the components come from, our in-house inventory, or trusted suppliers, we provide comprehensive electronic manufacturing services utilizing cutting-edge technology and highly skilled technicians, certified to the highest standards of J-STD-001 and IPC-A-610 Class II and III. We maintain a strict ISO 9001:2015-certified quality management system and state-of-the-art facilities to ensure every assembly meets exact specifications and quality standards.

Comprehensive Electronic Manufacturing Capabilities

Regardless of where the components come from, our in-house inventory, or trusted suppliers, we provide comprehensive electronic manufacturing services utilizing cutting-edge technology and highly skilled technicians, certified to the highest standards of J-STD-001 and IPC-A-610 Class II and III. We maintain a strict ISO 9001:2015-certified quality management system and state-of-the-art facilities to ensure every assembly meets exact specifications and quality standards.

Request Your Quote Today

To learn more about our contract manufacturing services, please contact AMS today or request your rapid quote to get your next project started.

Cable and Wire Harness Assembly

Experienced, Dedicated, and Committed to Customer Satisfaction

Your One Source for Dependable Cable and Wire Harness Assemblies

Advanced Manufacturing Service, Inc. is a trusted provider of high-quality and dependable custom cable and wire harness assembly services to a diverse range of customers . Our reliable harnesses provide optimum cable management, reducing the spaghetti that can result in extended downtime and potential safety hazards. These cable and wire harnesses play a vital role in ensuring reliable connections for consistent signal transmissions, particularly when the completed electronic devices will be used in harsh environments prone to extensive vibrations, such as those in industrial and aerospace applications.

Your One Source for Dependable Cable and Wire Harness Assemblies

Advanced Manufacturing Service, Inc. is a trusted provider of high-quality and dependable custom cable and wire harness assembly services to a diverse range of customers . Our reliable harnesses provide optimum cable management, reducing the spaghetti that can result in extended downtime and potential safety hazards. These cable and wire harnesses play a vital role in ensuring reliable connections for consistent signal transmissions, particularly when the completed electronic devices will be used in harsh environments prone to extensive vibrations, such as those in industrial and aerospace applications.

Comprehensive Assembly Capabilities

AMS has extensive experience building a wide range of harness assemblies, from basic single-wire assemblies to complex cable and wire harnesses with multiple branches and connectors. Our team of highly skilled technicians undergo continual training to ensure a comprehensive understanding of the latest trends in harness assembly boards, ensuring accurate assembly for optimal performance and cable management. We proudly offer complete turnkey or consigned materia l capabilities, providing our customers with flexible assembly options.

Our state-of-the-art facility houses the industry’s leading electronic manufacturing capabilities, which allow us to provide our customers with a single source for their electronic manufacturing requirements. Our comprehensive services include:

- Printed circuit board assemblies (SMT, PHT, RoHS and Non RoHS).

- Electro-mechanical assemblies and box builds.

- Prototype fabrication and functional testing.

Advanced Manufacturing Service: Delivering Quality Excellence in Cable and Wire Harness Assembly

At AMS, we ensure the durability and reliability of our custom cable and wire harnesses through our robust ISO 9001:2015-certified quality management system. Every assembly is built in a strict EDS environment and our technicians are certified to J-STD-001 and IPC-A- 610 Class II and III. This dedication to quality has earned us a reputation for exceeding customer expectations since 2007.

To learn more about our cable and wire harness assembly services, please contact Advanced Manufacturing Service or request a quick quote today!

Prototype Fabrication

Quick Quotes, Rapid Results

Accelerating Your Success with Rapid PCB Prototype Fabrication

Advanced Manufacturing Service, Inc. proudly maintains a comprehensive and cutting-edge manufacturing facility in Ronkonkoma, N.Y to provide our customers with rapid delivery of their PCB prototypes, from quote to delivery, in as little as a week. Manufactured and assembled in the United States by highly skilled experts under the strict standards of our ISO 9001:2015-certified quality management system ensures on-time delivery of functional and high-quality PCB and electronic assembly prototypes.

Accelerating Your Success with Rapid PCB Prototype Fabrication

Advanced Manufacturing Service, Inc. proudly maintains a comprehensive and cutting-edge manufacturing facility in Ronkonkoma, N.Y to provide our customers with rapid delivery of their PCB prototypes, from quote to delivery, in as little as a week. Manufactured and assembled in the United States by highly skilled experts under the strict standards of our ISO 9001:2015-certified quality management system ensures on-time delivery of functional and high-quality PCB and electronic assembly prototypes.

Extensive Inventory of High-Quality Electronic Components

To better serve our customers’ printed circuit boards design fabrication and assembly requirements, AMS maintains an extensive inventory of the industry’s leading electronic components from trusted name-brand manufacturers. We also foster strong partnerships with suppliers to ensure prompt delivery of specialized components. Our vast in-house inventory allows us to rapidly assemble functional prototypes in as little as five days.

Printed Circuit Board Fabrication and Assembly

We specialize in low to medium volume high-mix PCB assembly and maintain a strict EDS-protected manufacturing environment. Our state-of-the-art facility houses extensive PCB design fabrication and assembly capabilities, including:

- Surface Mount Assembly

- Through-Hole Assembly

- RoHS and Non RoHS Assembly

- Cable and Wire Harness Assembly

- Electro-Mechanical Assembly

- Box Builds

Our team of highly skilled technicians undergo extensive training to maintain the rigorous standards of their J-STD-001 and IPC-A-610 Class II and III certifications.

Printed Circuit Boards Design Fabrication and Assembly

We specialize in low to medium volume high-mix PCB assembly and maintain a strict EDS-protected manufacturing environment. Our state-of-the-art facility houses extensive PCB design fabrication and assembly capabilities, including:

- Surface Mount Assembly

- Through-Hole Assembly

- RoHS and Non RoHS Assembly

- Cable and Wire Harness Assembly

- Electro-Mechanical Assembly

- Box Builds

Our team of highly skilled technicians undergo extensive training to maintain the rigorous standards of their J-STD-001 and IPC-A-610 Class II and III certifications.

Dedicated to Quality Since 2007

Advanced Manufacturing Service has spent almost 20 years continuously improving the quality of our products and services, ensuring cost-competitive solutions to dependable electronic contract manufacturing with the reassurance that comes with American-made quality.

For more information please contact the experts at AMS or request your quote today and have your PCB prototype in as little as seven days.

Contact us for a quotation

For a quick quotation on our services, please fill in your details below.